T-Type vs Inline Filter Configurations

When considering high-pressure filtration options, two common choices are T-Type and Inline filters. 3B Filters, Inc provides many options in both configurations. Both configurations serve the purpose of removing contaminants and maintaining system cleanliness, there are distinct differences between the two.

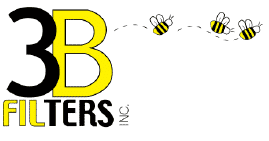

T-Type filters are designed with a configuration that resembles the letter “T.” They typically consist of a housing with an inlet and outlet on one side and a perpendicular connection for the filter element on the other side. This design allows for easy removal and replacement of the filter element, without the need to disconnect the inlet and outlet connections. T-Type filters are commonly used in applications where quick and convenient filter changes are required, such as in hydraulic systems, industrial processes, and water treatment. If space is a concern, 3B Filters, Inc offers our 8100 T-Type series which is compact and light weight. Our most commonly bought T-Type series is the 8500 series.

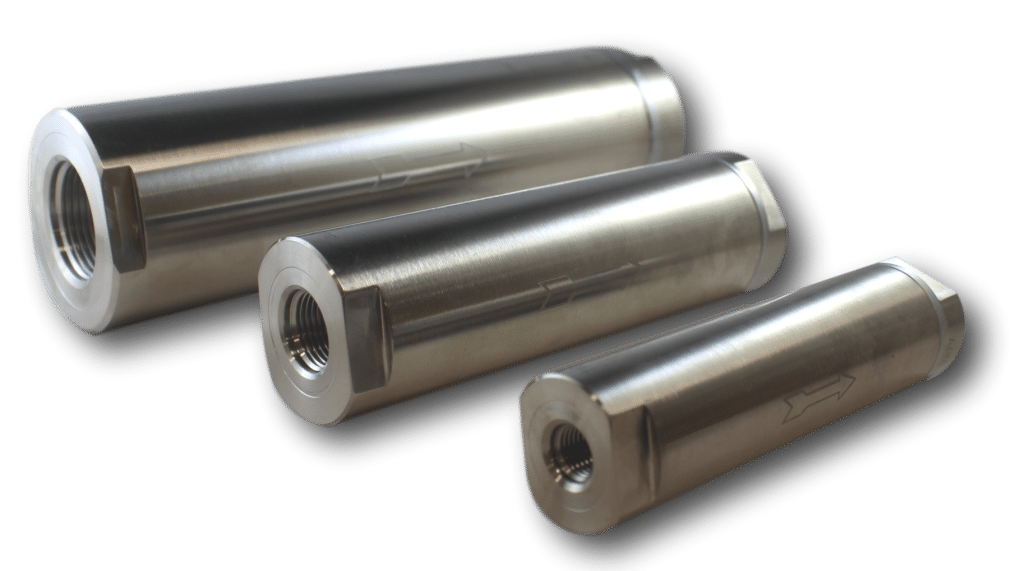

Inline filters, on the other hand, are directly installed into the fluid or gas line, typically in a straight configuration. They feature an inlet and outlet connection that align with the flow path, providing continuous filtration without interruption. Inline filters are often used in applications where space is limited or when a constant flow of fluid or gas is critical, such as in automotive engines, fuel systems, and pneumatic systems. Our 8200 and 8800 series offer the most compact footprint, with the 8800 series featuring a replaceable filter disc.

In terms of maintenance and serviceability, T-Type filters offer the advantage of easier element replacement since the housing does not need to be disconnected from the system. This can minimize downtime and simplify routine maintenance tasks. Inline filters, however, may require more time and effort to replace the filter element, as the inlet and outlet connections need to be disconnected and reconnected during the process.

When it comes to filtration capabilities, both T-Type and inline filters can effectively remove contaminants, particles, and impurities from fluids and gases. The choice between the two depends on the specific application requirements, space limitations, and maintenance considerations.

In summary, T-Type filters excel in applications that prioritize quick and convenient filter changes, while inline filters are suitable for situations where continuous filtration and space optimization are key factors. Ultimately, selecting the most appropriate filter type depends on the specific needs and constraints of the system or process in which it will be utilized. Our sales team can help you select the appropriate configuration for your system. Contact us today!